Transition fitting, steel pipe, spigot

Transition fitting for steel pipe, spigot USTRS

- Gas

- Maximum pressure: Gas 10 bar

- Material: PE 100 and steel [ISO 3183 / API5L]

Note:

To be utilised with the fusion couplers UB.

Anchored the steel side non-detachable and non-rotatable in the PE.

Steel pipe batch characterised by re-stamping of the pipe connection.

PE 100 SDR 11

Maximum permissible working pressure 10 bar (gas)

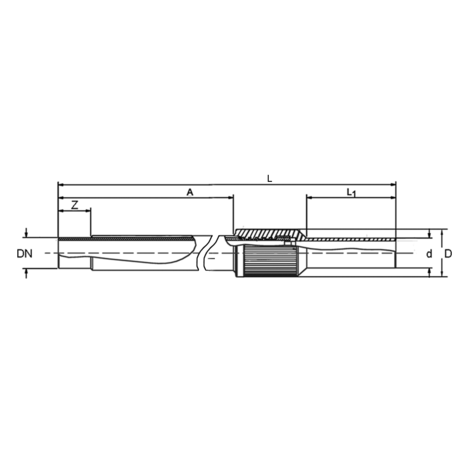

| Reference | d/DN | A | D | L | L1 | w | Weight kg | BX | PU |

|---|---|---|---|---|---|---|---|---|---|

| 616632 | 20/15 | 250 | 45 | 425 | 80 | 2,60 | 0,450 | 21 | 630 |

| 616633 | 25/20 | 285 | 45 | 460 | 90 | 2,60 | 0,650 | 21 | 630 |

| 616634 | 32/25 | 285 | 51 | 460 | 95 | 3,20 | 0,950 | 18 | 540 |

| 616635 | 40/32 | 285 | 63 | 470 | 100 | 3,20 | 1,250 | 12 | 360 |

| 616636 | 50/40 | 285 | 70 | 480 | 110 | 3,20 | 1,450 | 8 | 240 |

| 616637 | 63/50 | 275 | 89 | 480 | 110 | 3,60 | 2,150 | 6 | 216 |

| 616638 | 75/65 | 310 | 95 | 540 | 130 | 3,60 | 2,950 | 2 | 98 |

| 616639 | 90/80 | 310 | 117 | 580 | 140 | 4,00 | 3,950 | 2 | 98 |

| 616640 | 110/100 | 295 | 150 | 585 | 145 | 5,40 | 7,050 | 2 | 50 |

| 616641 | 125/100 | 295 | 150 | 585 | 150 | 5,40 | 7,300 | 2 | 50 |

| 616642 | 140/125 | 320 | 163 | 580 | 155 | 5,00 | 8,000 | 1 | 25 |

| 616643 | 160/150 | 290 | 210 | 610 | 160 | 5,00 | 10,500 | 1 | 25 |

| 616644 | 180/150 | 290 | 210 | 610 | 170 | 5,00 | 11,000 | 1 | 25 |

| 616645 | 200/200 | 300 | 259 | 630 | 155 | 6,30 | 17,500 | 1 | 16 |

| 616646 | 225/200 | 300 | 259 | 610 | 145 | 6,30 | 18,000 | 1 | 16 |

| 616647 | 250/250 | 300 | 324 | 640 | 140 | 6,30 | 30,500 | 1 | 8 |

| 616648 | 280/250 | 300 | 324 | 640 | 160 | 6,30 | 31,000 | 1 | 8 |

| 616649 | 315/300 | 315 | 368 | 725 | 220 | 8,80 | 46,500 | 1 | 6 |

| 616650 | 355/300 | 315 | 368 | 735 | 260 | 8,80 | 48,000 | 1 | 6 |

| 616651 | 400/400 | 350 | 475 | 770 | 190 | 8,80 | 83,200 | 1 | 3 |

| 616652 | 500/500 | 350 | 590 | 1050 | 365 | 10,00 | 127,500 | 1 | 2 |

| 616653 | 630/600 | 360 | 735 | 1100 | 430 | 12,70 | 242,000 | 1 | 2 |

Please note the mandatory labels directly on the product.

DVGW test mark issued with Reg. No.:

- DG-7521CR0259

- DW-7511CR0156

Welding ends according to standard: ASTM A106, DIN EN ISO 3183 (w = wall thickness of steel pipe)

Material steel ISO 3183 / API5L.

Areas of Application

The FRIALEN Transition Fittings USTRS are adapters to connect HD-PE pipes to steel pipes. The HD-PE spigot end has to be connected to a HD-PE pipe with FRIALEN Couplers. The steel spigot end of the USTRS has to be connected with a welding process to a steel pipe.

The front face of the steel pipe is according to ASTM A106 and DIN EN ISO 3183.

Assembly Instructions

The connection of the steel side happens with arc welding. Due to the heat dissipation only arc welding is permissible.

The fusion of the PE spigot end with a FRIALEN coupler takes place by using FRIALEN fusion process – leakproof and longitudinally strong.

The welding of the steel end and the fusion of the HD-PE side have to be prepared according to the general installation in-

struction (see ”Transition Fittings” in ”Assembly Instructions” for ”FRIALEN-Safety Fittings for house connections and distribution pipes”). This involves removing the oxide layer and cleaning the pipe ends.

Good reasons for using the FRIALEN-Transition Fitting USTRS:

- Steel end permanently anchored in the HD-PE and will not distort

- Little insulating work due to coated steel pipe

- HD-PE side with spigot end for processing without holding device, designed for FRIALEN couplers

- Pull-proof connection

- Compact construction

- Additional barcode for tracing back the fitting (Traceability-Coding)

- Oxidic layer may be removed from PE spigot end using scraper tools

get_app

get_app

get_app

get_app