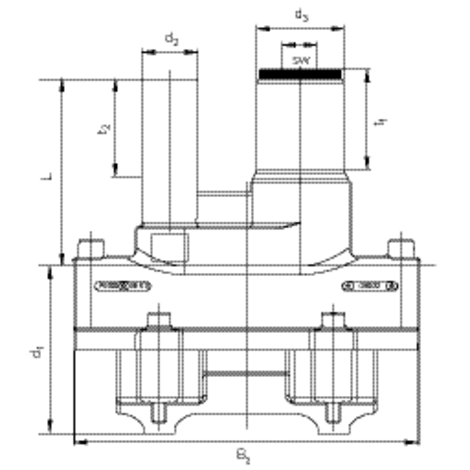

Horizontal tapping tee, SDR 11

Horizontal tapping tee DAP SDR 11

- Gas and water

- Working pressure: MOP (gas) 10 bar, PFA (water) 16 bar

- Material: PE 100

- Conventional clamping technology (brackets and screws)

- Vertical outlet for special solutions:

- Space-saving installation

- With 90 degree elbow and ball valve = Rotatable dome 360 degrees

- Leak test possible before drilling.

- Integrated drill with upper and lower inner stop

- Sealing plug with internal sealing O-ring

- Safety technology

- DVGW test mark: DV-8601AU2248 and DV-8606AU2249

Note:

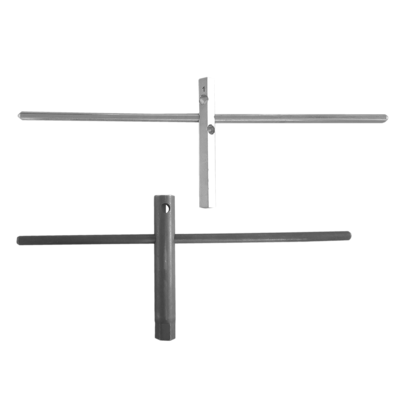

Utilise the operating key FWSS SW 17 for d 63 (Order No. 613246) or FWSS SW 19 from d 90 (Order No. 613250).

There is a suitable pressure test adapter FWDPA for DAP (Order No. 613595).

PE 100 SDR 11

Maximum permissible working pressure 16 bar (water) / 10 bar (gas)

| Reference | d1 | d2 | d3 | L | t1 | t2 | product.detail.attribute.anbarm | Weight [kg] | BX | PU |

|---|---|---|---|---|---|---|---|---|---|---|

| 616042 | 63 | 32 | 40 | 125 | 50 | 84 | 21 | 0,630 | 16 | 288 |

| 615581 | 110 | 32 | 50 | 158 | 58 | 115 | 30 | 1,280 | 12 | 96 |

| 615606 | 110 | 50 | 50 | 158 | 58 | 115 | 30 | 1,340 | 12 | 96 |

| 615711 | 125 | 32 | 50 | 158 | 58 | 115 | 30 | 1,340 | 12 | 96 |

| 615712 | 125 | 50 | 50 | 158 | 58 | 115 | 30 | 1,330 | 12 | 96 |

| 615713 | 160 | 32 | 50 | 170 | 70 | 115 | 30 | 1,540 | 8 | 64 |

| 615714 | 160 | 50 | 50 | 170 | 70 | 115 | 30 | 1,560 | 8 | 64 |

| 615715 | 180 | 32 | 50 | 170 | 70 | 115 | 30 | 1,550 | 6 | 48 |

| 615716 | 180 | 50 | 50 | 170 | 70 | 115 | 30 | 1,570 | 6 | 48 |

| 615717 | 225 | 32 | 50 | 170 | 72 | 115 | 30 | 1,570 | 6 | 48 |

| 615718 | 225 | 50 | 50 | 170 | 72 | 115 | 30 | 1,590 | 6 | 48 |

FRIALEN pressure tapping tees ≤ d 63 are applicable for pipes of SDR level 11 and > d 63 for pipes of SDR level 11 to 17.6. Minimum wall thickness s minimum ≥ 3 mm. Other levels of SDR can be processed on request. Please note the mandatory labels directly on the product. DVGW test marks issued: DV-8601AU2248 and DV-8606AU2249.

Areas of Application

The FRIALEN DAP is used for HD-PE pipe systems both in the water and gas industry. The outlet spigot has been designed to be extra long. These pressure tapping tees are particularly suited for space-saving horizontal installation.

Assembly Instructions

The fusion of the HD-PE distribution pipes and the house connections with FRIALEN-Pressure Tapping Tees takes place by FRIALEN-fusing –leakproof and longitudinally strong.

The saddle and the outlet spigot have to be prepared according to the general installation instructions (see “Assembly Instructions” for “FRIALEN-Safety Fittings for house connections and distribution pipes up to d 225”). This involves removing the oxide skin and cleaning the pipe covered by the saddle.

Good reasons for using FRIALEN DAP Pressure Tapping Tees:

- Economy due to space-saving horizontal installation. Excavation depth of pipe system trenches reduced by 10-20 cm

- Protection from damage during subsequent work in the trench through the dome and outlet being positioned below the mains pipe apex

- Length of the outlet spigot measured for 2 fusions

- Additional barcode for tracing back the underground fitting (Traceability-Coding)

In addition, all tried-and-tested advantages of a FRIALEN Pressure Tapping Tee apply:

- Drill guidance through metallic threaded coupling

- No gas escapes during drilling process

- Little force required for drilling

- Secure position of the cut-out calotte in the drill

- Upper and lower end position

- Broad fusion zone

- Valve dome can be fused with the seal cap after drilling

- No shavings on drilling

- Possible to carry out leakage check before drilling

get_app

get_app

get_app

get_app