Transition fitting HD-PE/V2A with male thread

Transition fitting V2A pipe MUN V2A

- Water

- Maximum pressure: Water 16 bar

- Material: PE 100 and V2A [EN 10278, EN 10088-3 - 1.4305 -X8CrNiS18-9, thread according to EN 10226-1]

- Safety technology

Note:

V2A side is anchored in the PE so that it cannot be rotated.

Self-sealing, patented sealing geometry without elastomeric seal for utilisation in water areas.

Other thread dimensions available on request.

PE 100 SDR 11

Maximum permissible working pressure 16 bar (water)

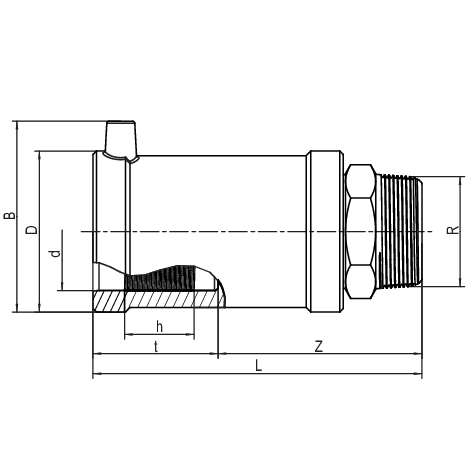

| Reference | d | R | B | D | h | L | t | z | Weight kg | BX | PU |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 616516 | 40 | 1" | 70 | 58 | 30 | 123 | 46 | 75 | 0,460 | 20 | 800 |

| 612727 | 40 | 1 1/2" | 70 | 58 | 30 | 127 | 46 | 78 | 0,495 | 20 | 800 |

| 612726 | 50 | 1 1/2" | 80 | 70 | 30 | 137 | 53 | 84 | 0,600 | 15 | 600 |

| 612705 | 63 | 1 1/2" | 94 | 84 | 35 | 137 | 53 | 84 | 0,865 | 10 | 400 |

| 612899 | 63 | 2" | 94 | 84 | 35 | 142 | 53 | 89 | 0,910 | 10 | 400 |

For stockstatus 3, acceptance only in complete packaging units.

Other thread dimensions on request

FRIALEN safety fittings can be fused with SDR11 - SDR17.6 pipes, minimum wall thickness s minimum ≥ 3 mm. Other levels of SDR can be processed on request. Please note the mandatory labels directly on the product.

DVGW test marks issued: DV-7501AU2256 and DV-7501AU2257

Areas of Application

FRIALEN-Transition Fittings MUN-V2A are threaded joints as an adaptor from a metal pipe with internal thread to a HD-PE pipe. Joint on the part of HDPE by FRIALEN-Coupler. The threaded joint is made of stainless steel (Material St. 1.4305 / X8CrNiS18-9).

Assembly Instructions

During assembly, only a spanner applied to the provided metal hexagon must be used to screw the component into its metal counterpart. The fusion of the HD-PE side takes place by FRIALEN-fusing – leakproof and longitudinally strong.

The installation of the stainless steel and the HD-PE side has to be prepared according to the general installation instructions (see ”Transition Fittings with threaded connection” in ”Assembly Instructions” for ”FRIALEN-Safety Fittings for house connections and distribution pipes up to d 225”). This involves removing the oxide skin and cleaning the pipe ends.

Good reasons for using the FRIALEN-Transition Fittings MUN-V2A:

- Compact construction

- HD-PE side with exposed heating element for optimal heat transfer

- Cold zones at the end to prevent the flow of molten material

- No holding clamps required

- Large insertion depth, extra wide fusion zones

- Stainless steel end permanently anchored in the HD-PE and will not distort

- Self sealing patented sealing geometry without elastomer seal

- Additional barcode for tracing back the underground fitting (Traceability-Coding)

- Threaded joint made of stainless steel (St. 1.4305) = resistant to corrosion

- Suitable for usage in high humidity environment or in industrial area

get_app

get_app

get_app

get_app