Product:

FIP UPVC piping system (pipes, fittings and valves), FIP PP/steel loose flanges, PE pipes and FRIALEN safety fittings

The Challenge

With the construction of a new production hall at the Mannheim site, the demand for high-performance and sustainable cooling technology for the injection molding machines increased. The existing cooling system – a cooling tower with a recooling unit – was outdated and no longer met the increased requirements in terms of energy efficiency, capacity and water consumption. Aliaxis Germany responded with targeted investments in modern cooling systems to future-proof the production infrastructure and make it more resource-efficient.

The Solution

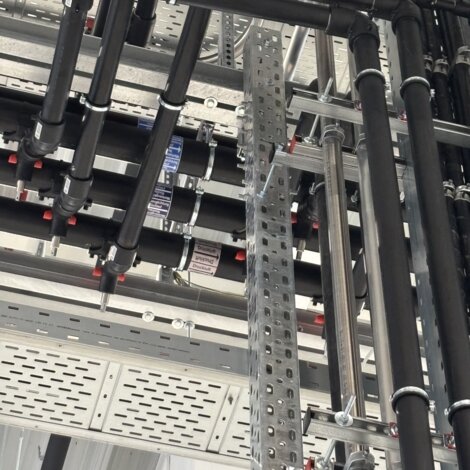

The new cooling water supply is based on two separate systems with new piping made of PE and UPVC. For above-ground installation within the production hall, the choice fell on polyethylene (PE) – a material known for its high corrosion resistance, long service life, and excellent processing properties. PE had already proven itself in a previous cooling water project in 2014, when both the piping and the cooling water tank were custom-made from PE.

The connection between the cooling system and the injection molding machines was implemented using PE piping systems and FRIALEN safety fittings. For maximum flexibility during installation and future expansions, the DAV RED SNAP pressure tapping valve was used – an innovative alternative to the traditional T-piece, ideal for subsequent adjustments.

The cooling system itself is housed in a container outside the hall. The connection to the production hall was made using the FIP PVC-U piping system. The installation was complemented by modern, energy-efficient pump systems that reduce electricity consumption and enable sustainable operation.

The Realisation

The technical implementation was carried out by the company Technotrans, based on specifications from Aliaxis Germany. Close coordination between planning and execution enabled smooth integration into the existing infrastructure and a future-oriented design of the new cooling water systems.

The Conclusion

With the new cooling water supply, Aliaxis Germany has created a closed system solution that significantly reduces water consumption while minimizing the risk of contamination. The use of energy-efficient pump technology and modern refrigerants optimizes the entire cooling process. The investment in sustainable technology and durable materials such as PE underscores Aliaxis's commitment to environmental responsibility and the continuous development of the Mannheim site.