Top-loading tapping tee, SDR 11

Top-loading tapping tee DAA TL SDR 11

- Gas and water

- Working pressure: MOP (gas) 10 bar, PFA (water) 16 bar

- Material: PE 100

- Universal clamping option (top loading):

- Safe clamping with FRIATOP

- Universal adaptation to pipe diameter

- Leak test possible before drilling

- Integrated drill with upper and lower inner stop

- Sealing plug with internal sealing O-ring

- Safety technology

- DVGW test mark: DV-8606AU2249 and DV-8611AU2250

Note:

Can only be fused with the clamping device FRIATOP (Order No. 613350).

Only one actuating key FWSS SW 19 (Order No. 613250) for all dimensions.

There is a suitable pressure test adapter FWDPA for DAA TL (Order No. 613595).

From dimension d 355 to d 400, the DAA TL is only suitable for SDR 17 pipes.

PE 100 SDR 11

Maximum permissible working pressure 16 bar (water) / 10 bar (gas)

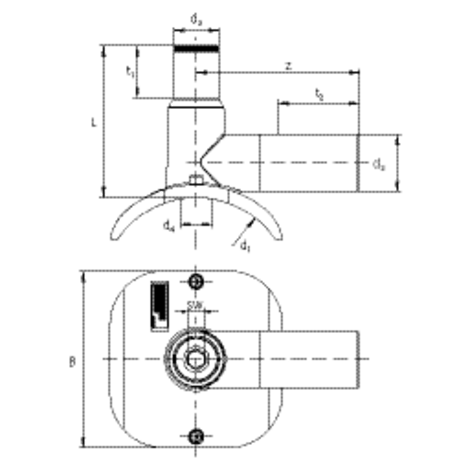

| Reference | d1 | d2 | B | D1 | d3 | L | t1 | t2 | z | Drilling Ø da | Weight [kg] | BX | Pallet quantity |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 615339 | 250-315 (- 400) | 63 | 195 | 250-315 (- 400) | 50 | 167 | 58 | 118 | 180 | 30 | 1,450 | 4 | 72 |

d1: d 250 to d 315 for SDR 11 and 17 pipes;

d1: d 355 and d 400 just for SDR 17 pipes

Other outlet dimensions with reducing couplers MR.

Areas of Application

The FRIALEN DAA TL and DAA TL RE Pressure Tapping Tees are used for branches of unpressurised and pressurised pipelines for variable adaption to all pipe diameters in the given range.

Outlet spigots prepared for receiving gas flow controllers. Dimensions on request.

Assembly Instructions

The fusion of the HDPE distribution pipes and the house connections with FRIALEN-Pressure Tapping Tees takes place by FRIALEN-fusing – leakproof and longitudinally strong.

The saddle and the outlet spigot have to be prepared according to the general installation instructions (see “Assembly Instructions” for “FRIALEN-Safety Fittings for house connections and distribution pipes up to d 225” and “FRIALEN-Special Technology for laying large bore pipes and relining pipe networks”). This involves removing the oxide skin and cleaning

the pipe covered by the saddle as well as the outlet spigot and the pipe end. Component is clamped onto the pipe using the FRIALEN clamping device FRIATOP.

Good reasons for using the FRIALEN DAA TL and DAA TL RE:

- Compact construction

- Safe clamping of component using the FRIATOP clamping unit

- Preassembled unit without loose parts

- Leakage check possible before tapping

- Swarfless tapping

- Leakage-free tapping of gas pipe up to 10 bar working pressure

- Little force required for tapping

- Punched-out pipe piece fits securely in drill

- Drill guided in metal sleeve

- Drill with upper and lower stop

- Extra wide fusion zone

- Dome can be fused with cap after tapping

- Length of outlet spigot dimensioned for two fusion operations

- Additional barcode for tracing back the underground fitting (Traceability-Coding)

get_app

get_app

get_app

get_app