Tapping ball valve Top loading for side tapping under pressure

Tapping ball valve AKHP TL

- Gas and H2

- Working pressure: MOP (gas) 10 bar

- Material: PE 100

- Gasket: NBR

- 1/4 turns for opening and closing

- Top load saddle

- Safety technology

- DVGW test mark: DG-8631AU2252 and DG-8631AU2253

Note:

Can only be used with the clamping device FRIATOP (Order No. 613350).

For this purpose, there is a suitable installation kit KBS for wrench sizes SW14 (14 mm) and SW30 (30 mm).

For tapping under pressure, we recommend the drilling tool from Hütz & Baumgarten (www.huetz-baumgarten.de).

From dimension d 450 to d 560 only suitable for SDR17.

PE 100 SDR 11

Maximum permissible working pressure 10 bar (gas)

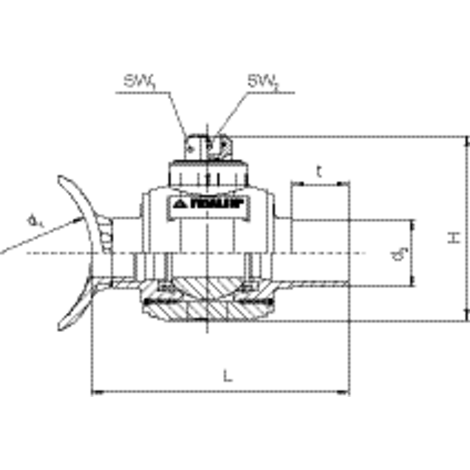

| Reference | d1 | d2 | D1 | H | L | t | Drilling Ø da | SW1 | SW2 | Weight [kg] | BX | Pallet quantity |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 615526 | 250-450 (- 560) | 90 | 250-450 (- 560) | 240 | 335 | 90 | 60 | 50 x 50 | 25 | 4,470 | 4 | 32 |

Areas of Application

The FRIALEN-Tapping Ball Valve, completely made from HD-PE, makes it possible to tap sideways into an operational HD-PE mains under gas and water pressure (no drinking water!) – without any escape of gas or water.

DVGW test marks issued AKHP-TL: DG-8631AU2252 and DG-8631AU2253

Assembly Instructions

For this version the saddle will be mounted using the FRIATOP Clamping Unit (see list of Technical Equipment). Please read the separate leaflet “Assembly and Operating Instructions for FRIATOP clamping unit (Top-Loading)”.

The fusion of FRIALEN Tapping Ball Valves to the HD-PE main takes place by FRIALEN fusing – leakproof and longitudinally strong. The pipe and the saddle have to be prepared (oxide layer removal/cleaning) in accordance with the general installation instructions (see „Assembly Instructions“ for FRIALEN XL for laying large pipes and relining pipe networks).

Tapping of the HD-PE pipe under operating pressure

For this we recommend the tapping equipment of Hütz + Baumgarten. It is clamped onto the exposed fusion end of the ball valve. The tapping of the HD-PE pipe takes place through the opened ball valve and is leakage free. Observe the notes on the boarding equipment.

Actuating the shut-off valve

By the telescopic actuating installation kit KBS from the valve cover.

Good reasons for using the FRIALEN-Tapping Ball Valves:

- Fusioning and tapping under pressure saves time-consuming and expensive shut-offs and emergency supply during the integration

- Installation of mains and service lines takes place on one level and thus affords advantages in the planning stages

- Construction and connecting works are reduced to a minimum

- The ball valve can be used as a shut-off device afterwards

- Can be applied universally to large HD-PE pipe diameters d 250-450 (560). This means additional economy due to less material needed

- Additional barcode for tracing back the underground fitting (Traceability-Coding)

get_app

get_app

get_app

get_app