Misalignment bridge, SDR 11

Misalignment bridge WET, SDR 11

- Gas, water and H2

- Working pressure: MOP (gas) 10 bar, PFA (water) 16 bar

- Material: PE 100

- Bridging when the pipe alignment is offset

- Safety technology

- DVGW test mark: DV-8601AU2248

Note:

At the dimension d 63, 90 degree elbows are utilised.

Ideal for the parallel laying of two main pipes or for the house connection pipe to the tapping valve DAV or the tapping tees DAA.

PE 100 SDR 11

Maximum permissible working pressure 16 bar (water) / 10 bar (gas)

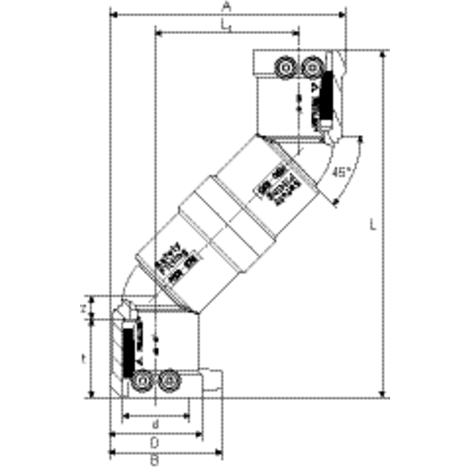

| Reference | Diameter | SDR range | A | B | D | L | L1 | t | z | Weight [kg] | BX | Pallet quantity |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 616051 | 32 | 11 | 123 | 63 | 49 | 177 | 74 | 42 | 10 | 0,230 | 15 | 750 |

| 616052 | 40 | 11 | 147 | 72 | 58 | 215 | 89 | 49 | 14 | 0,330 | 15 | 480 |

| 616053 | 50 | 11 - 17,6 | 171 | 83 | 70 | 242 | 101 | 53 | 16 | 0,510 | 15 | 270 |

| 616699 | 63 | 11 - 17,6 | 256 | 96 | 84 | 172 | 172 | 55 | 31 | 0,760 | 10 | 180 |

Areas of Application

The FRIALEN Swan Neck Bend WET is applied:

- for the connection of pipes which do not approach each other in alignment, for example the connection of the outlet spigot of a pressure tapping tee with the domestic pipe via earth rocket technology,

- where two mains are installed parallel and at the same height. Between the outlet spigot of the pressure tapping tee DAA/DAV and the domestic pipe a deviation leap is necessary to run above the second pipe.

FRIALEN safety fittings can be fused with SDR11 - SDR17.6 pipes.

Minimum wall thickness s minimum ≥ 3 mm.

Other levels of SDR can be processed on request.

Please note the mandatory labels directly on the product.

DVGW test mark issued: DV-8601AU2248

Assembly Instructions

The fusion of the pipe ends with the FRIALEN Swan Neck Bend WET takes place by FRIALEN-fusing – leakproof and longitudinally strong. The pipe ends are prepared according to the general installation instructions (see “Assembly Instructions” for “FRIALEN-Safety Fittings for house connections and distribution pipes up to d 225”). This involves removing the oxide skin and cleaning the pipe ends.

Good reasons for using the FRIALEN-Swan Neck Bend WET:

- Complete prefabricated part to connect not aligned outlet spigot and pipe end

- Large coupler depth for ease of pipe guiding (no holding clamps required)

- Extra wide fusion zones

- Maximum stability through great wall thickness

- Cold zones at the front side and in the middle of the coupler

- Exposed heating coil for direct heat transmission to the pipe

- Small annular gap for build-up of optimum joining pressure in the fusion zone

- Contacts safe to touch

- Durable batch marking

- Individually wrapped for dirt protection

- Additional barcode for tracing back the underground fitting (Traceability-Coding)

get_app

get_app

get_app

get_app