Gas-Stop by Pipelife

Gas-Stop FRIASTOP with integrated Gas-Stop System by Pipelife

- Gas and H2 (100 %)

- Working pressure:

- Type U, UUE and S, SOU MOP (Gas) 5 bar

- Type A/D MOP (Gas) 1 bar

- Material: PE 100-RC

- Overflow device for Type A/D, UUE and S

- Without overflow device for Type U and SOU

- Function to admixture of 100 % hydrogen

- Safety technology

- DVGW test mark: DV-8601AU2248 and DG-4360BP0060 (DVGW G 5305-2)

PE 100-RC SDR 11

Maximum permissible working pressure Type U, UUE, S, SOU: 5 bar (gas), Type A/D: 1 bar (gas)

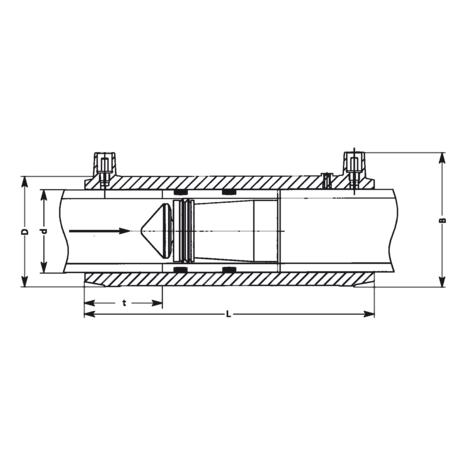

| Reference | Diameter | Type | D | L | t | Operating pressurerange pmin - pmax | VN | Weight [kg] | BX | Pallet quantity |

|---|---|---|---|---|---|---|---|---|---|---|

| 616199 | 32 | U | 45 | 136 | 38 | 35 mbar - 5 bar | 16 - 38 | 0,140 | 40 | 1280 |

| 616201 | 50 | U | 68 | 175 | 54 | 35 mbar - 5 bar | 38 - 91 | 0,360 | 20 | 640 |

| 616203 | 63 | U | 82 | 197 | 59 | 35 mbar - 5 bar | 58 - 140 | 0,560 | 12 | 384 |

| 616200 | 32 | UUE | 45 | 136 | 38 | 35 mbar - 5 bar | 16 - 38 | 0,140 | 40 | 1280 |

| 616202 | 50 | UUE | 68 | 175 | 54 | 35 mbar - 5 bar | 38 - 91 | 0,360 | 20 | 640 |

| 616204 | 63 | UUE | 82 | 197 | 59 | 35 mbar - 5 bar | 58 - 140 | 0,560 | 12 | 384 |

| 616205 | 32 | A/D | 45 | 136 | 38 | 25 mbar - 1 bar | 10 - 14 | 0,140 | 40 | 1280 |

| 616207 | 50 | A/D | 68 | 175 | 54 | 25 mbar - 1 bar | 25 - 36 | 0,360 | 20 | 640 |

| 616209 | 63 | A/D | 82 | 197 | 59 | 25 mbar - 1 bar | 40 - 55 | 0,560 | 12 | 384 |

| 616339 | 32 | S | 45 | 136 | 38 | 200 mbar - 5 bar | 36 - 80 | 0,140 | 40 | 1280 |

| 616340 | 50 | S | 68 | 175 | 54 | 200 mbar - 5 bar | 110 - 240 | 0,360 | 20 | 640 |

| 616341 | 63 | S | 82 | 197 | 59 | 200 mbar - 5 bar | 180 - 400 | 0,560 | 12 | 384 |

| 617353 | 32 | SOU | 45 | 136 | 38 | 200 mbar - 5 bar | 36 - 80 | 0,140 | 40 | 1280 |

| 617354 | 63 | SOU | 82 | 197 | 59 | 200 mbar - 5 bar | 180 - 400 | 0,560 | 12 | 384 |

Areas of Application

FRIASTOPP is used for gas and service lines according to DVGW G459-1 appendix (12/03) with operating pressure from 25 mbar – 5 bar.

FRIASTOPP is a safety device which automatically cuts off the gas flow in the event of pipe damage, e.g. caused by dredging or drilling.

FRIASTOPP is best installed in the branch between mains and service line, immediately behind the service line valve.

The Pipelife Gas-Stop™ type selection takes place according to the minimum operating pressure and the required flow output based on consumption.

The universal type U covers the practical requirements of the operating pressure range and the required flow volume perfectly. Type U is available without, or as Type UUE, with surplus flow opening.

pmin - pmax: min. - maximum. working pressure or inlet pressure Pipelife Gas-Stop™.

VN: Nominal flow rate in m3/h at pmin or pmax (natural gas d = 0.6 at 1013.25 mbar, 0°C).

The universal Type U optimally covers the practical requirements for the working pressure range and the required flow rate. Type U is available without or as Type UUE with overflow opening. The special Type S is intended for high nominal flows and is adapted to the flow capacities of commercially available pressure regulating devices.

Type A/D, UUE, S: FRIASTOPP - Pipelife Gas-Stop™ with overflow device

Overflow quantities

A/D: 30 l/h at 100 mbar

UUE and S: 30 l/h at 1 bar.

Type U, SOU: FRIASTOPP - Pipelife Gas-Stop™ without overflow device

Leak rate: 3.0 l/h.

Other types available on request.

FRIALEN safety fittings can be fused with pipes with SDR levels 11 to 17.6. Minimum wall thickness s minimum ≥ 3 mm. Other SDR levels available on request. Please note the mandatory labels directly on the product. DVGW test marks issued: FRIALONG = DV-8601AU2248.

Pipelife Gas-StopTM to DVGW G 5305-2 (01.10.2013) = DG-4360BP0060.

Functions

(see also leaflet on technical data “Pipelife Gas-Stop™” by Pipelife Austria GmbH & Co KG, http://www.pipelife-gasstop.com).

FRIASTOPP shuts off automatically at a defined gas flow as typically occurs with damaged gas service lines. Gas flow is cut off instantaneously and completely. The types A/D, UUE and S have surplus flow devices. The surplus flow amount available increases the pressure in the intact gas line allowing the Gas-Stop™ to reopen automatically.

Type A/D, UUE and S: Pipelife Gas-Stop™ with surplus flow device:

Surplus flow amounts over 30 l/h require additional passive safety measures according to DVGW-G459-1-B.

Type U without surplus flow opening are reopened when counter pressure (approx. mains pressure) is applied. It does not need to be made accessible for this purpose.

Assembly Instructions

FRIASTOPP is to be processed according to the installation and operating instructions which come with each FRIASTOPP.

Constricting the gas route by means of FRIASTOPP is possible up to 10 bar regardless of whether the Gas-Stop™ is open or shut. The initial mains pressure of the component can be gleaned from the data plate:

- purple data plate (Type U) for 35 mbar to 5 bar

- blue data plate (Type A/D) for 25 mbar to 1 bar

- red data plate (Type S) for 200 mbar to 5 bar.

The use of this component should be marked at the main shut-off device of the building (appropriate label is included in the delivery).

Fusion of FRIASTOPP with the HD-PE service line takes place using the FRIALEN fusion process – leakproof and longitudinally strong.

Installation is prepared according to the general installation requirements (see “Assembly Instructions” for “FRIALEN Safety Fittings for house connections and distribution pipes up to d 225”), i.e. remove oxidic layer and clean.

Good reasons for using FRIASTOPP:

- Factory made combination made from FRIALEN long coupler and Pipelife Gas-Stop™

- The reduction of the cold zones by the integrated Pipelife Gas-StopTM is compensated in comparison to the standard coupler

- Each FRIASTOPP fitting is subject to a functional control in our works

- The exposed heating coil and the extra wide fusion zones ensure optimum heat transmission to the pipe

- Additional barcode for tracing back the underground fitting (Traceability-Coding)

- The fitting may be installed in any position

- Each FRIASTOPP is marked with a own serial number

- The type label is adhesive and can be directly applied for e.g. constructional logs

The Pipelife Gas-Stop™:

- has a low pressure loss

- is largely resistant to pollutants in the gas

- is made from plastic and is therefore corrosion resistant and has a long life

- is tried and tested millions of times in over twenty years

- an increase in operating pressure possible anytime with suitable mains

- is subject to a 100% function test

- Universal type U: universal application, simple storage, no danger of confusion, low operational training cost

- is easy to use

The Special Type S:

- is suitable for higher nominal flow rates

- enables an optimized dimensioning of connecting pipes

- the nominal flow rates meet the requirements of standard pressure regulators

get_app

get_app

get_app

get_app