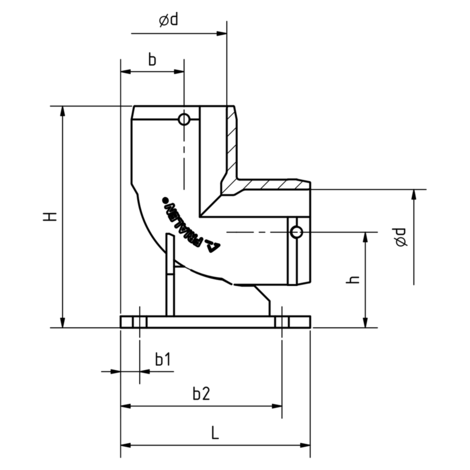

Elbow with duck foot, SDR 11

Elbow with duck foot WF SDR 11

- Water

- Working pressure: PFA (water) 16 bar

- Material: PE 100

- Angle 90 degrees

- Assembly on the foundation possible

- Safety technology

- DVGW Registration No.: DV-8606AU2249

Note:

Ideal for the hydrant connection adjacent to main pipe.

PE 100 SDR 11

Maximum permissible working pressure 16 bar (water)

| Reference | d | SDR range | b | b1 | H | h | L | Weight [kg] | BX | PU |

|---|---|---|---|---|---|---|---|---|---|---|

| 617485 | 90 | 11 - 17,6 | 104 | 25 | 265 | 120 | 248 | 2,260 | 3 | 54 |

| 617486 | 110 | 11 - 17,6 | 83 | 25 | 290 | 125 | 248 | 2,940 | 1 | 32 |

FRIALEN safety fittings can be fused with pipes with SDR levels 11 to 17.6.

Other SDR levels available on request.

Please note the mandatory labels directly on the product.

DVGW test mark issued: DV-8606AU2249

Areas of Application

The FRIALEN-Elbow with Base Unit WF 90° allows for connection of a hydrant alongside the mains.

The hydrant connection takes place either

- by fusing the HD-PE pointed end of the hydrant with the construction part or

- for a hydrant with flange connection by applying the FRIALEN-Full Faced Flange EFL* or with a Flange Reduction FLR** d 110/DN 80.

Connection to the HD-PE mains takes place without pressure via the FRIALEN-Spigot Saddle SA d 110/90-225/110 (see Data Sheet No. 27 and leaflet) or under operating pressure with an additional cut-off device. For drilling into the mains we recommend drilling equipment by Hütz + Baumgarten.

Assembly Instructions

Please refer to the FRIALEN “Assembly Instructions” for preparations for the FRIALEN-fusion process (two fusion procedures) of the elbow piece with HD-PE pipes or HD-PE pipe and HD-PE valve (marking insertion depth, removing oxide skin, cleaning, etc.).

* (see Data Sheet EFL No. 46)

** (see Data Sheet FLR No. 61)

Good reasons for using the FRIALEN-Elbow with base unit WF 90°:

- Great wall thickness ensures optimum stability and safe positioning of the hydrant

- Separate fusion zones enable simple tension-free fusion

- Floor plate can be mounted directly onto foundations

- Base unit and elbow make up a homogeneous unit

- Large coupler depth for ease of guidance of pipe and construction part

- Small annular gap for build-up optimum joining pressure in the fusion zone

- Extra wide fusion zones

- Cold zones at the front side and in the middle of the coupler

- Exposed heating coil for optimum heat transfer onto pipe/construction part

- Additional barcode for tracing back the underground fitting (Traceability-Coding)

get_app

get_app

get_app

get_app