Ball valve for water

Ball valve KHW for water

- Water

- Working pressure: PFA (water) 16 bar

- Material: PE 100

- Gasket: EPDM

- 1/4 turns for opening and closing

- with full bore

- DVGW test mark: DW-6210CQ0059

Note:

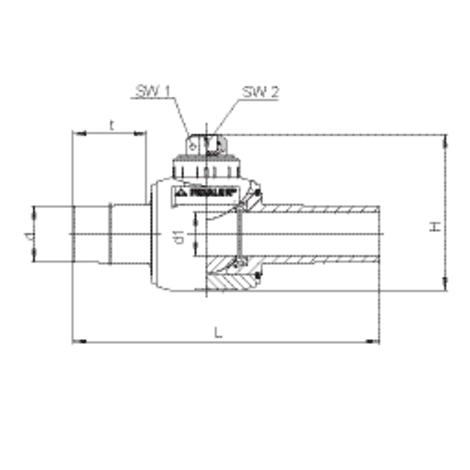

For this purpose, there is a suitable installation kit KBS for wrench sizes SW14 (14 mm ) and SW30 (30 mm).

From dimension d 50, utilise a KBS d 63 - d 225.

PE 100 SDR 11

Maximum permissible working pressure 16 bar (water)

| Reference | Diameter | d1 | D1 | H | h | h1 | L | t | SW1 | SW2 | Weight [kg] | BX | Pallet quantity |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 616656 | 32 | 34 | 34 | 156 | 48 | 92 | 324 | 108 | 50 x 50 | 20 | 0,650 | 1 | 100 |

| 616657 | 40 | 34 | 34 | 156 | 48 | 88 | 324 | 108 | 50 x 50 | 20 | 0,700 | 1 | 100 |

| 616658 | 50 | 43 | 43 | 204 | 70 | 109 | 405 | 129 | 50 x 50 | 25 | 2,220 | 1 | 50 |

| 616659 | 63 | 51 | 51 | 206 | 70 | 104,5 | 410 | 134 | 50 x 50 | 25 | 2,380 | 1 | 48 |

Areas of Application

The FRIALEN-Ball Valve KHW with EPDM-sealing with drinking water approval is suitable for shutting off sections of the main and also for isolating house connection pipes. The Ball Valve KHW can be applied in pipe systems for water supply, for compressed sewage, mineral and sea water pipes.

Further media on request.

The passage of the valve (d1) corresponds approx. with the internal diameter of the pipe socket SDR without constriction.

The Ball Valve KHW is opened and closed by a 1/4-turn with the installation kit KBS. The installation kit KBS allows the operation from the street cap and is optimal adapted to the FRIALEN-Ball Valve KHW. For further information see this data sheet page 2. or data sheet installation kit KBS No. 22/00.

FRIALEN safety fittings can be fused with pipes with SDR levels 11 to 17.6. Minimum wall thickness s minimum ≥ 3 mm. Other levels of SDR can be processed on request. Please note the mandatory labels directly on the product.

DVGW test mark issued: DW-6210CQ0059

Assembly Instructions

The FRIALEN-Ball Valve KHW is connected to the pipe by using Couplers, Elbows or T-Pieces fused to its ends.

The connection with HD-PE pipes takes place by FRIALEN-fusing – leakproof and longitudinally strong.

The spigot ends to be fused are prepared according to the general installation instructions (see “Assembly Instructions” for “FRIALEN-Safety Fittings for house connections and distribution pipes up to d 225”). This involves removing the oxide layer and cleaning the pipe ends.

Before fusion the FRIALEN-Ball Valve KHW must be lined up to suit the type of actuation intended, in order to ensure that the installation kit KBS will placed correctly.

Good reasons for using the FRIALEN-Ball Valve KHW:

- The FRIALEN-Ball Valve provides a completely fused HD-PE pipe network, without transitions to other materials or flange connections

- Another step towards a pure PE-pipe system

- Optimum hydraulics due to pipe identical passage and contour providing ease of flow

- Good testability due to lack of constriction of internal diameter

- Floating ball, axial seals in the ball axle and combination of ball guidance and ball seal in one part compensate for bending defects

- No deposits on internal areas, resistant to chemical and electrical reactions

- No corrosion proofing required

- Optimum hydraulics due to pipe identical passage and contour providing ease of flow, optimum flow speed

- Low activating element, low weight

- Extra long spigot ends dimensioned for two fusion operations

- Actuating of the KHW with the telescopable installation kit KBS

- Additional barcode for tracing back the underground fitting (Traceability-Coding)

get_app

get_app

get_app

get_app