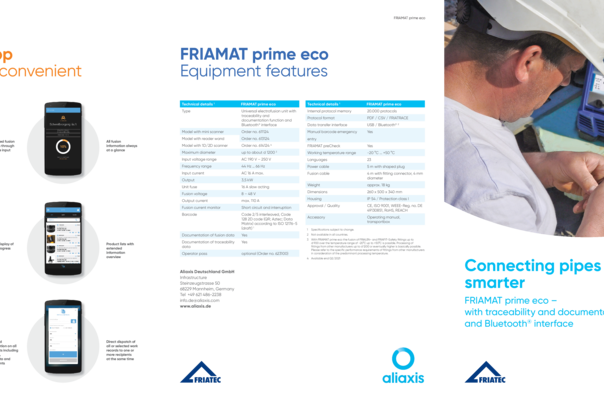

Fusion unit with documentation function

Powerful universal fusion unit FRIAMAT Prime eco

- Bluetooth

- Full documentation

- Full traceability functions

- 20,000 fusion protocols

- Output via USB interface or app (smart phone)

- Supervisor function

- Toroidal core technology with active cooling.

- Bright colour TFT display

- With mini scanner or 1D/2D scanner (2D barcodes according to ISO 12176-5)

- Extra long fusion cable (4 m)

- Extra long power cable (5 m)

- Weight approx. 18.0 kg

Note:

Possibility of updating the FRIAMAT software via the USB interface by the user.

| Reference | Short text | Weight [kg] | BX | PU |

|---|---|---|---|---|

| 611124 | With mini scanner | 19,900 | 1 | 4 |

| 614124 | With 1D/2D scanner | 19,900 | 1 | 4 |

Technical data 1) |

FRIAMAT Prime eco 2) |

Type of device |

Universal electrofusion unit with traceability and documentation function and Bluetooth interface |

Model with mini scanner |

Order no. 611124 |

Model with 1D/2D scanner |

Order no. 614124 |

Maximum diameter |

Up to d 1200 3) |

Input voltage section |

AC 190 V – 250 V |

Frequency range |

44 Hz … 66 Hz |

Current consumption |

AC 16 A maximum |

Power |

3.5 kW |

Unit fuse |

16 A sluggish |

Welding tension |

8 – 48 V |

Output current |

maximum 110 A |

Welding current monitoring |

Short circuit and interruption |

Barcode type |

1D-Code 2/5 interleaved, Code 128, 2D-Code (QR; Aztec; Data Matrix) according to ISO 12176-5 |

Interface |

USB / Bluetooth® Low Energy V4.2 (CE, FCC, IC certified) |

Documentation of fusion data |

Yes |

Documentation of traceability data |

Yes |

Data memory |

20.000 protocols |

Log format |

PDF / CSV / FRIATRACE |

Manual emergency barcode input |

Yes |

FRIAMAT preCHECK function |

Yes |

Software update via USB interface |

- |

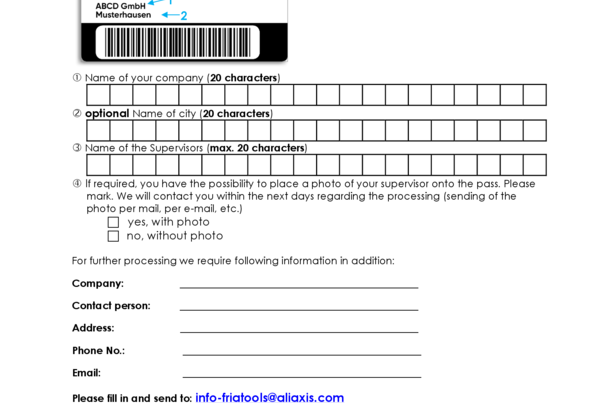

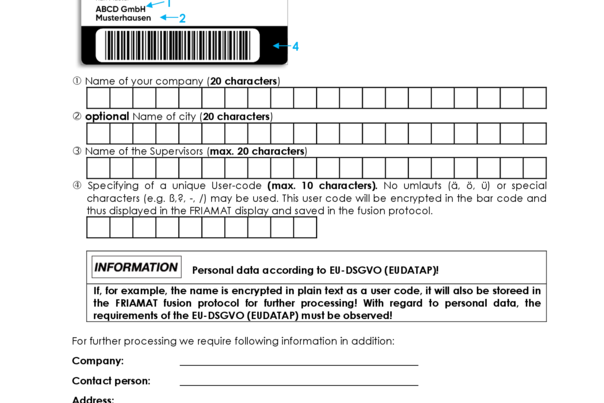

Fusion-Pass |

Optional (Order no. 623100) |

Supervisor-Pass |

Yes |

Start/stop pass for remote control |

Optional (Order no. 624003) |

Working temperature range |

-20 °C ... +50 °C |

Language variants |

23 |

Connection cable |

5 m with contour plug |

Fusion cable |

4 m with connection plug Ø 4 mm |

Weight |

approx. 18 kg |

Dimensions W x D x H |

260 x 500 x 340 mm |

Casing |

Protection category IP 54 / protection category I |

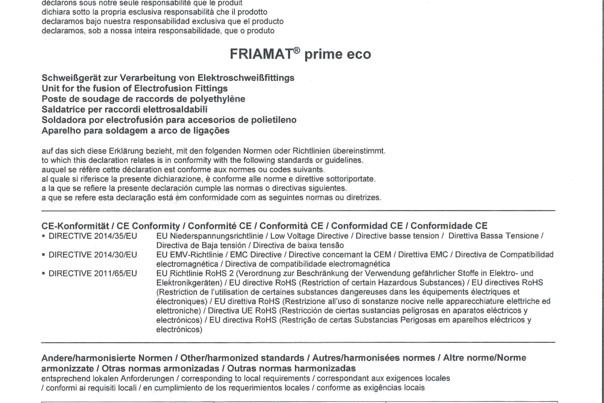

Approval / quality |

CE, ISO 9001, WEEE-Reg. no. DE 49130851, RoHS, REACH |

Accessories |

Operating instructions, transport box |

1) Subject to technical modifications.

2) From year of construction Q2/2021

3) With the FRIAMAT prime eco, FRIALEN and FRIAFIT safety fittings up to d 900 can be fused in the entire working temperature range of -20 °C +50 °C.

Utilising processing fittings from other manufacturers is possible even up to d 1200 and possibly larger. However, the specific power requirement of the fitting at the prevailing processing temperature must always be clarified beforehand with the fitting manufacturer.

- High performance due to innovative toroidal transformer technology with flow-optimized, active cooling.

- High-resolution, extremely bright 4.3 “TFT color display. Documentation of fusion and traceability data. Memory space for up to 20,000 fusion logs. CSV or PDF file or FRIATRACE format output to standard USB stick.

- With mini-scanner, reader wand or new 1D/2D scanner for reading 2D barcodes according to ISO 12176-5, Adapter bag, language selection, adjustable buzzer volume, manual emergency entry. Extra-long power cable (4 m) and extra-long fusion cable (5 m). Weight approx 18 kg.

- Continuous monitoring of the entire fusion process and all device functions.

- With FRIAMAT preCHECK function: The most advanced way to fuse with foresight. The FRIAMAT automatically determines whether the next fusion can be performed completely to the end.

- The user himself can install software updates via USB interface.

- Integrated Bluetooth function for communication with the FRIAMAT App. At present, the use of the Bluetooth function is only permitted in the following countries: Australia - Austria - Belgium - Bulgaria - Croatia - Cyprus - Czech Republic - Denmark - Estonia - Finland - France - Germany - Great Britain - Greece - Hungary - Iceland -Israel - Ireland - Italy - Latvia - Liechtenstein - Lithuania - Luxembourg - Malta - the Netherlands - Norway - Poland - Portugal - Romania - Serbi - Slovakia- - Slovenia - Spain - Sweden - Switzerland - New Zealand

get_app

get_app

get_app

get_app