Flange T-piece, SDR 11

Flange T-piece TFL

- Water

- Maximum pressure: Water 16 bar (SDR 11), 10 bar (SDR 17)

- Material: PE 100 and metal insert

- Safety technology

Note:

Reduction and fusion flange. Metal insert in flange in order to prevent cold flow.

We recommend GST seals.

Note the screw tightening torques after specifying the seal manufacturer or DVS.

Additional washers are required.

PE 100 SDR 11Maximum permissible working pressure 16 bar (water)

PE 100 SDR 11

Maximum permissible working pressure 16 bar (water)

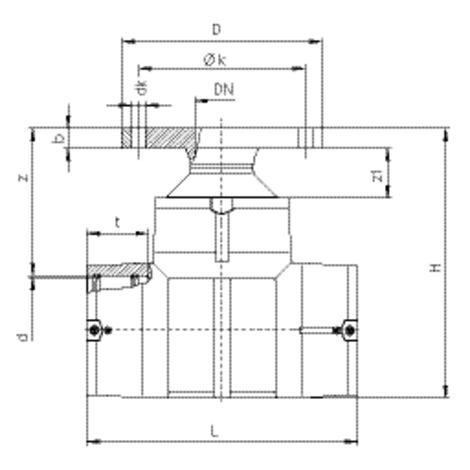

| Reference | d/DN | D | dk | H | Ø k | L | t | z | z1 | Holes | Weight kg | BX | PU |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 615590 | 110/80 | 204 | 17 | 316 | 160 | 355 | 87 | 190 | 42 | 8 | 4,920 | 4 | 32 |

| 615591 | 125/80 | 204 | 17 | 343 | 160 | 384 | 87 | 190 | 45 | 8 | 5,480 | 3 | 24 |

| 615592 | 160/80 | 204 | 17 | 390 | 160 | 430 | 96 | 210 | 50 | 8 | 8,050 | 2 | 16 |

| 615910 | 180/80 | 204 | 17 | 416 | 160 | 480 | 103 | 210 | - | 8 | 10,000 | 1 | 8 |

PE 100 SDR 17Maximum permissible working pressure 10 bar (water)

PE 100 SDR 17

Maximum permissible working pressure 10 bar (water)

| Reference | d/DN | D | dk | H | Ø k | L | t | z | Holes | Weight kg | BX | PU |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 616031 | 225/80 | 204 | 17 | 465 | 160 | 580 | 118 | 210 | 8 | 15,420 | 2 | 4 |

FRIALEN safety fittings can be fused with pipes with SDR levels 11 to 17.6. Other levels of SDR can be processed on request. Please note the mandatory labels directly on the product. DVGW test mark issued: DV-8606AU2249

Areas of Application

The FRIALEN Flange T-Piece is used for the transition between HD-PE pipes to pipes or valves made from metal. The main area of application of the FRIALEN Flange T-Piece is the hydrant connection. For a branch line in DN 80 you can flange directly a shut-off valve. Other nominal diameters can be also realised with the FRIALEN T-Piece1) in combination with FRIALEN flange reducer FLR respectively if the nominal diameter is equal with the FRIALEN Full faced flange EFL2).

Assembly Instructions

The Flange T-Piece is installed only in pressure-free condition. Please refer to the FRIALEN-Assembly Instructions with regard to the preparations of the T-Piece in the direction of the passage opening with HD-PE pipes (marking of insertion depth, removing oxide skin, cleaning, etc.) for FRIALEN fusion.

Flange connection measurements correspond to DIN EN 1092-1.

Supplementary washers are necessary.

All standard profile or flat gaskets can be used. Please observe screw torque specifications as indicated by the gasket manufacturer. We recommend G-ST gaskets.

1) see Data Sheet No. 10

2) see Data Sheet No. 46

Good reasons for using the FRIALEN Flange T-Piece FLT:

- Compact part in HD-PE for direct connection to flanged valves and hydrants

- Factory made combination made from FRIALEN T-Piece, Reducer and Weld in flange (fixed flange)

- Optional installation position (upright or horizontal position)

- No inner fusion ridge on the fused seam of the reducer

- No ”cold-flow characteristics” at the flange due to constructive design

- Short dimensions with regard to height and length

- Particularly economical solution

- T-Piece with exposed heating coils for optimal heat transfer, large insertion depth, wide fusion zones plus cold zones at the end and in the middle to prevent the flow of molten material

- Additional barcode for tracing back the underground fitting (Traceability-Coding)

get_app

get_app

get_app

get_app