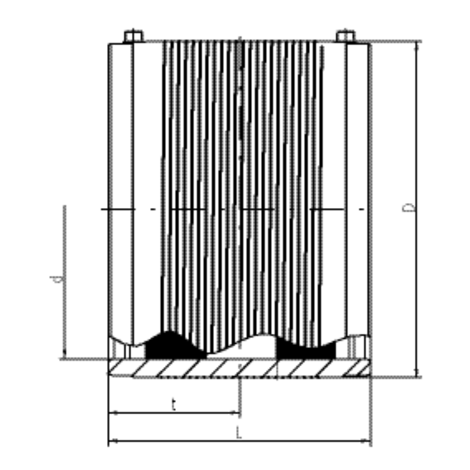

Coupler without inner stop, SDR 17

Coupler without inner stop, SDR 17

- For connecting water and sewage pipes made from HD-PE

- Safety technology

- For processing without holding devices

- With pin indicator for visual inspection of the fusion

- DVGW test mark: DV-8606BO6114 (d 110 - d 225)

PE 100 SDR 17

Maximum permissible working pressure 10 bar (water / sewage)

| Reference | d | SDR range | D | L | t | Weight kg | BX | PU | |

|---|---|---|---|---|---|---|---|---|---|

| 680001 | 110 | 33 - 17 | 130 | 160 | 80 | 0,600 | 24 | 192 | |

| 680013 | 125 | 33 - 17 | 146 | 160 | 80 | 0,650 | 22 | 176 | |

| 680002 | 160 | 33 - 17 | 184 | 180 | 90 | 1,100 | 12 | 96 | |

| 680003 | 180 | 33 - 17 | 207 | 180 | 90 | 1,450 | 8 | 64 | |

| 680004 | 200 | 33 - 17 | 236 | 180 | 90 | 2,070 | 1 | 75 | |

| 680005 | 225 | 33 - 17 | 263 | 200 | 100 | 2,723 | 1 | 52 | |

| 680006 | 250 | 33 - 17 | 282 | 220 | 110 | 2,200 | 1 | 44 | |

| 680007 | 280 | 33 - 17 | 316 | 220 | 110 | 3,800 | 1 | 32 | |

| 680008 | 315 | 33 - 17 | 355 | 220 | 110 | 4,750 | 1 | 24 | |

| 680009 | 355 | 33 - 17 | 400 | 220 | 110 | 5,900 | 1 | 24 | |

| 680010 | 400 | 33 - 17 | 450 | 220 | 110 | 7,300 | 1 | 12 | |

| 680011 | 450 | 33 - 17 | 506 | 270 | 135 | 11,200 | 1 | 6 | |

| 1 | 680012 | 500 | 33 - 17 | 562 | 270 | 135 | 14,450 | 1 | 4 |

DVGW test mark issued: DV-8606BO6114

Sewage pipe systems are high-value assets of a value which has to be maintained for a long time. Increasing demands on the public sewage system require materials which meet these criteria. HDPE sewage pipes have been fused for many years with the FRIAFIT HDPE sewage system tightly, frictionlocked and root-proof.

Areas of Application

The FRIAFIT-Coupler AM joins HDPE pipes leakproof and longitudinally strong.

Additional applications:

- Integration of adapters into existing pipe system

- Jointing to pipelines with a fixed or forced point

- Reinforcement/sealing of local pipe damage.

Assembly Instructions

Fusion of pipe ends with FRIAFIT-Coupler AM takes place using FRIAFIT fusion – leakproof and longitudinally strong.

The HDPE pipe ends are prepared according to the general installation requirements (see also “Fitting Instructions” for the FRIAFIT-Sewage System). This involves removing the oxide layer and cleaning the pipe ends.

To compensate a larger annular gap (> 1 mm, max. 3 mm) between coupler and pipe, the pre-heating barcode can be used from d 560 (see instructions packed up with the coupler).

FWSG scraper tools are available for the removal of the oxide layer, which enable uniform swarf removal and reproducible quality of the fusion area preparation.

Good reasons for using the FRIAFIT-Coupler AM:

- Ensures leakproof, longitudinally strong and root-bound connections

- Exposed, tightly embedded heating coil for direct heat transmission to the pipe

- Large coupler depth for ease of pipe guiding (no holding clamps required)

- Extra wide fusion zones, extra long insertion depths

- Short fusion times, short cooling times

- Cold zones at the front side and in the middle of the coupler

- Slide-over coupler without center stop

- Fusion indicator for visual fusion control

- From d 250: No coupler extension during fusion due to the outer armouring wire

- From d 560: Pre-heating technology for an optimal compensation of the annular gap

- Barcode for fully automatic fusion with HDPE pipes from SDR 33 to SDR 17 having regard to the ambient temperature (temperature compensation)

get_app

get_app

get_app

get_app