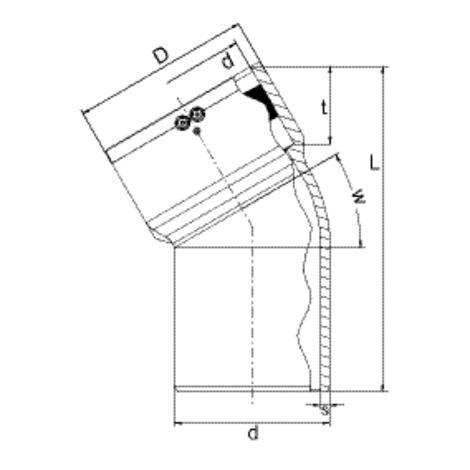

Sewage bend (one-side spigot end)

Sewage bend (one-side spigot end) ABMS

- Low space requirement through compact design. The gradations 15°, 30°, 45° enable comfortable services routing

- Fem. connection side with safety technology

- Pipe spigot particularly suitable for direct fusion into the FRIAFIT sewage saddle ASA TL

- By multiple application with ABM, for example, elbows of 60°, 90°, etc. can also be achieved

- The smooth and hydraulically optimised internal contour provides a equal-base passage when utilising SDR 17/17.6 pipes

- Bright surface finish for optimum visibility when driving through with a camera

- With pin indicator for visual inspection of the fusion.

PE 100

Maximum permissible working pressure 2.5 bar

| Reference | d | D | L | s | t | w | Weight kg | BX | PU |

|---|---|---|---|---|---|---|---|---|---|

| 681103 | 160 | 185 | 286 | 9,5 | 92 | 15° | 1,510 | 6 | 48 |

| 681104 | 160 | 185 | 329 | 9,5 | 92 | 30° | 1,680 | 6 | 48 |

| 681105 | 160 | 185 | 325 | 9,5 | 92 | 45° | 1,730 | 6 | 48 |

Sewage pipe systems are high-value assets of a value which has to be maintained for a long time. Increasing demands on the public sewage system require materials which meet these criteria. HDPE sewage pipes have been fused for many years with the FRIAFIT HDPE sewage system tightly, frictionlocked and root-proof.

Areas of Application

The FRIAFIT elbows ABM and ABMS d 160/DN 150 are used for change of direction in sewage and combined sewage water connection lines. The types ABM (coupler/coupler) or ABMS (coupler/pipe spigot) and the angle spacings 15°, 30° and 45° facilitate a comfortable piping configuration. Angles of 60°, 90° etc. can be produced by using multiple elbows. The FRIAFIT elbow ABMS is specifically suited for direct fusion into the FRIAFIT sewage saddle ASA-TL. The FRIAFIT elbows ABM and ABMS have a smooth, hydraulically optimised internal contour for sewage water draining and offer a level passage when used with

pipes SDR 17/17.6. The bright surface facilitates an optimal view during camera inspection. The material used is stabilised against UV radiation.

Notes on processing

The connection of the pipes and fittings with FRIAFIT elbows by FRIAFIT fusion is leak-tight and friction-locked. The PE fusion ends of the pipe or fitting are prepared according to the general installation

requirements (see assembly instructions for the FRIAFIT sewage system) (remove oxide layer/clean). For push-fit connections at the pipe spigot of the FRIAFIT elbow ABMS, insertion depths and wall

thickness differences, if any, are to be considered.

Good reasons for the FRIAFIT elbows ABM / ABMS

• Little space required thanks to compact design

• Reduction of the installation time thanks to

integrated fusion couplers

• Large coupler depths for good guiding of the

pipe or pipe spigot (no fixing devices required)

• Leak-tight, friction-locked and root-proof connection

• Exposed, fixed heating coil for direct heat transfer to the pipe

• Extra-broad fusion zones

• Extra-large insertion depths

• Short fusion times, short cooling down times

• Fusion indicator for visual control of fusion

• Extra-long cold zones before and after the fusion area

• Barcode for fully automatic fusion with HDPE pipes from SDR 33 to SDR 17, taking into

consideration the ambient temperature (temperature compensation)

• Bright component part interior surface for continuous camera inspection

• Hydraulically optimised internal contour through curved form

• Level when using SDR 17/17.6 connecting pipes, no drain obstructions

• Flexible use thanks to types ABM (coupler/coupler) or ABMS (coupler/pipe spigot)

• Elbow angle 15°, 30°, and 45°

• Other elbow angles can be produced by using multiple elbows or combining elbows

get_app

get_app

get_app

get_app